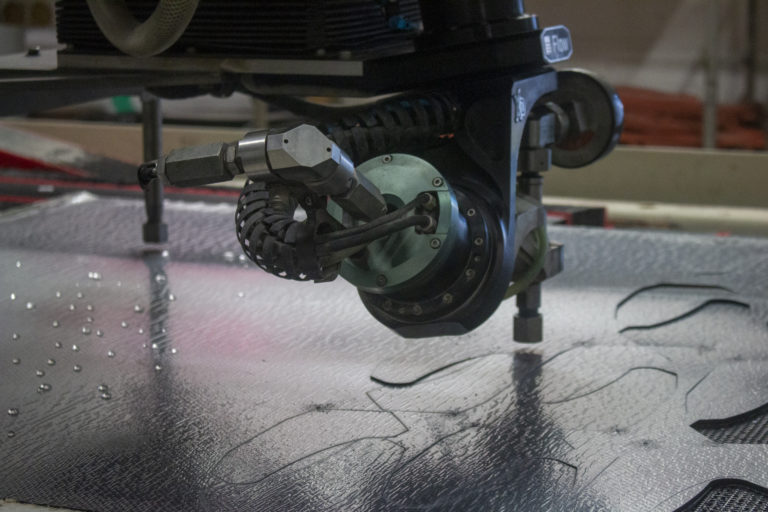

Water Jet Cutting

When the part calls for fine, intricate cuts with no room for error, water jet cutting is just the tool for the job. It’s often the go to for industries that demand lower tolerances and high precision for optimal performance, especially aerospace. As we design the production process for your custom converter, the following will outline when water jet cutting might play a role.

What is Water Jet Cutting?

Water jet cutting services deliver a narrow, pressurized stream of water to cut the shape from the material. An abrasive material is sometimes added to the water solution, especially when working with thick, heat-resistant foams or harder materials.

Why ABLE water jet cutting services, and when is it the best option?

- Water jet cutting uses el software de diseño asistido por computadora (CAD) para guiar el chorro de agua. Por esa razón, el corte por chorro de agua es altamente repetible en la producción, lo cual nos permite lograr resultados consistentes.

- Cuando llega el momento del prototipado rápido, el corte por chorro de agua es uno de los mejores métodos de corte. Debido a que es de fabricación asistida por computadora, si tiene archivos de diseño CAD listos, puede enviarlos y ABLE puede producir un prototipo en 48 horas.

- Water jet cutting can slice through just about any material, especially those that are difficult to cut, such as thicker foams, as well as materiales resistentes al calor, como por ejemplo, la silicona..

- La precisión del corte por chorro de agua lo hace ideal para tallar diseños intrincados, recortes y piezas pequeñas de material laminado.

Corte por chorro de agua versus corte por láser

Unlike laser cutting, water-jet cutting is a cold process. It does not produce or transfer any heat to the material. Unlike laser cutting, water-jet cuts leave behind no heat-affected zone or other physical changes in the material that can affect performance. This is why water-jet cutting is the go-to in aerospace applications where products must meet rigorous quality standards.