ABLE’s Advanced Router Knife Cutting Capabilities: Precision Fueling Success

Router knife cutting replaces manual labor with advanced technology by employing computer-controlled routers equipped with sharp blades to precisely create intricate patterns. The procedure begins with uploading a digital design to the router’s computer, which directs the cutting tool through various materials such as cardboard, foam, plastic, rubber, fabrics, and paper. In this industry, ABLE Converting is the standard, demonstrating a constant commitment to both quality and innovation. Precision is associated with great outcomes when using ABLE’s router knife cutting service on a wide range of materials and applications.

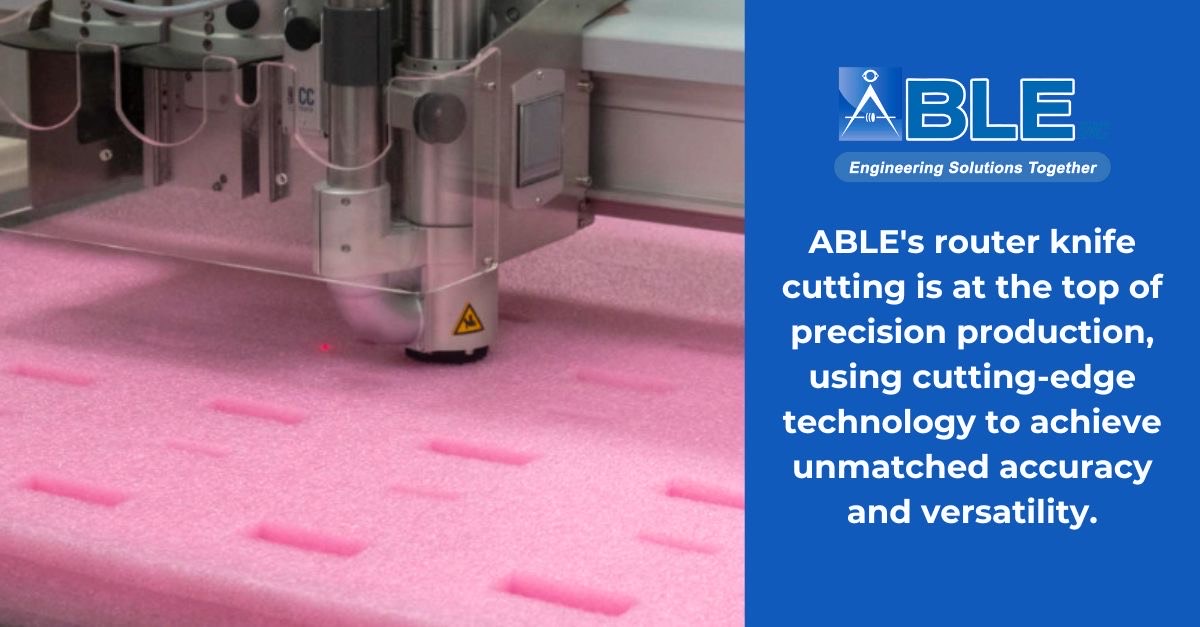

High-Level Precision with ABLE’s Router Knife Cutting

ABLE’s router knife cutting is at the top of precision production, using cutting-edge technology to achieve unmatched accuracy and versatility. With our top-notch equipment and experience, we excel at converting a wide range of materials, including foams, plastics, rubbers, fabrics, and papers, into precisely created components and products.

We start our process with a careful preparation of the design and then precisely adjust the cutting parameters based on the particular material and design requirements. The sharp blades on the computer-controlled routers allow them to cut with remarkable accuracy, resulting in consistency and uniformity across several parts. With our router cutting service, you may create complex package inserts, accurate car parts, or custom signage that satisfy the highest production and quality standards. ABLE is committed to precision, efficiency, and innovation for all of your cutting needs.

Common Materials Converted Using Router Knife Cutting

Router/knife cutting is an adaptable method that can be used to cut a variety of materials, such as:

- Foams: Various types of foam materials, such as polyurethane foam, polyethylene foam, and polystyrene foam, can be accurately cut using router cutting. Foam cutting is commonly used in industries such as packaging, insulation, and upholstery.

- Plastics: Router knife cutting is effective for cutting both rigid and flexible plastics, including acrylics, PVC, ABS, and polycarbonate. Plastic cutting applications range from signage and displays to automotive components and electronic enclosures.

- Rubbers: Rubber materials, such as silicone rubber, neoprene rubber, and EPDM rubber, can be precisely cut using router cutting. Rubber cutting is essential for manufacturing gaskets, seals, O-rings, and other automotive and industrial components.

- Fabrics and Textiles: Router cutting is suitable for cutting various fabrics and textiles, including cotton, polyester, nylon, and felt. Fabric cutting applications include apparel production, upholstery, soft furnishings, and textile-based crafts.

- Paper and Cardboard: This converting solution is widely used in the packaging and printing industries for cutting paper, cardboard, corrugated board, and other paper-based materials. It enables the production of custom packaging, displays, and promotional materials with intricate designs and precise dimensions.

ABLE’s Multi-Purpose Tool: The Zünd G3 Flatbed Cutter

The Zünd G3 flatbed cutter is at the top in router cutting adaptability and precision. With its extensive collection of cutting tools and modules, including router/knife cutting capabilities, this multi-purpose tool allows us to tackle a wide range of materials and applications with remarkable efficiency and accuracy.

The Zünd G3 flatbed cutter delivers consistently high-quality results by effortlessly changing between cutting methods, from fragile foam designs to precise plastic components. Its advanced automation features and computer-controlled precision ensure that each cut follows the strictest tolerances and quality standards, while its flexibility allows us to respond quickly to changing project requirements, making it an indispensable asset in our aim of cutting quality service.

ABLE’s Router Knife Cutting Capabilities Elevates Project Success

ABLE Converting is your trusted partner when it comes to router knife cutting for your projects. Our dedication to excellence and innovation means that each project receives the utmost attention to detail and precision, resulting in exceptional results. Our cutting-edge technology, including the Zünd G3 flatbed cutter, provides exceptional adaptability, allowing us to handle a wide range of materials and applications with ease. Additionally, the years of experience and knowledge that our team of skilled professionals offers to every project guarantees that your vision is skillfully transformed into reality.

Furthermore, because we value client satisfaction, we prioritize communication, collaboration, and flexibility throughout the process, ensuring that your needs are not just fulfilled, but exceeded. With precision, quality, and dependability at every stage, ABLE Converting is the preferred converter for industrial converting capabilities, whether you need quick prototypes, large-scale production runs, or customized solutions.

Are you ready to bring your projects to life with precision and efficiency? Look no further than ABLE’s cutting-edge router knife cutting capabilities. Contact us now to discuss how we can elevate your projects. Let’s turn your vision into reality!

References:

https://able123converting.com/capabilities/router-knife-cutting/

https://www.zund.com/en/cutting-systems/digital-cutting-systems/g3-cutter?details=integrated-tool-initialization

https://able123converting.com/blog/able-diverse-capabilities-for-custom-converting-solutions/