To create the shape you need for your part, you can’t go wrong with a custom die cut. With our full range of cutting-edge die cutting capabilities, our experts at ABLE will identify the perfect process to create a part that fits.

Die cutting is a fabrication process that cuts shapes from materials, such as adhesives, film, foam and rubber. Precision die cutting is an effective method for producing custom parts at high volume within a tight tolerance range. Read on to learn about the different ways ABLE’s die cutting can be deployed to fabricate your custom converted part.

To create your custom die cut converted part, ABLE can cut these materials alone, but they can also be layered, laminated and cut as one unit.

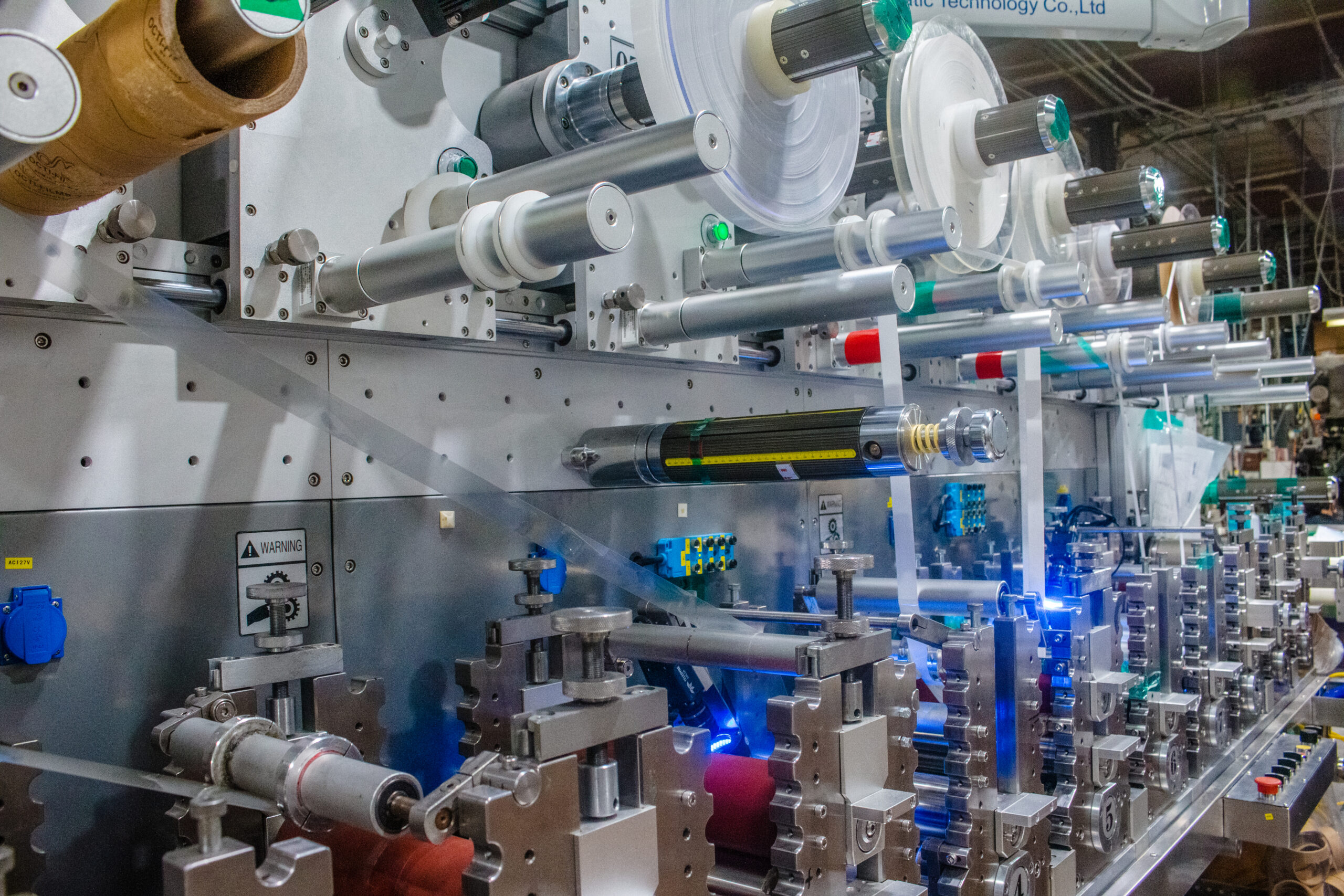

Rotary die cutting uses a cylindrical die to cut customized shapes from your chosen material. As the cylinder turns, the material passes under the blades of the die to create the desired shape.

ABLE rotary die cutting can create almost any shape from any custom material, ranging from film to converted materials, such as adhesive-backed foam. ABLE rotary die cutting is optimal for items that require a tight tolerance as well as high-volume orders requiring a tight turnaround.

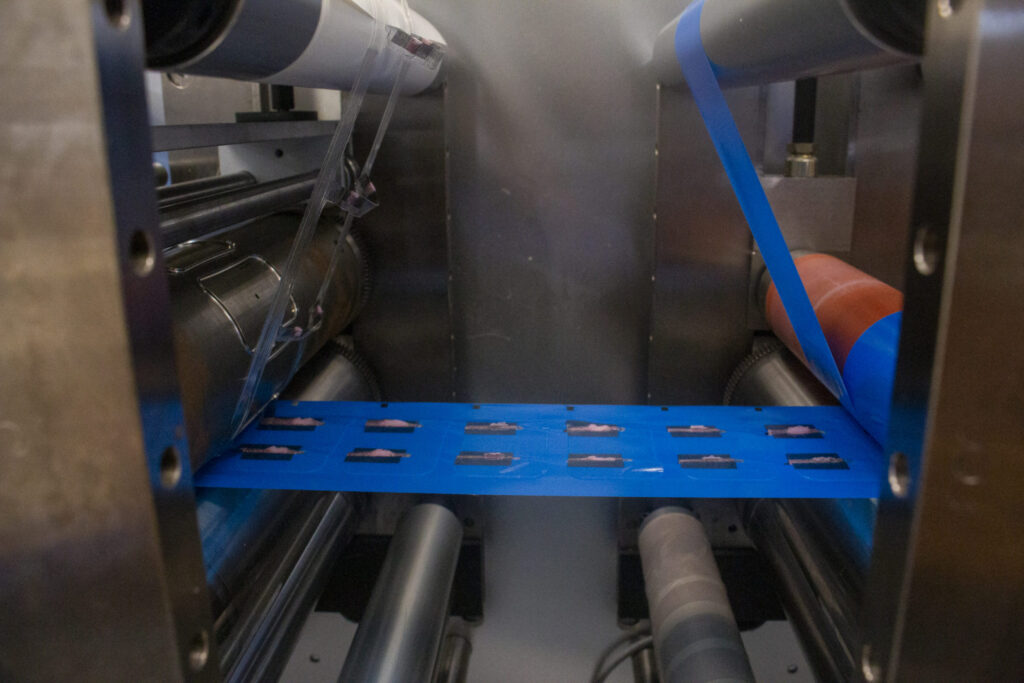

An ABLE kiss cutting is designed so the blade of the die stops short at the bottom layer of the material

or converted product. It makes an even, uniform cut, but not as deep as a metal-to-metal die cut.

A metal-to-metal cut means the blade of the die makes a complete pass through the entire layer of material.

For example, if you’re fabricating adhesive-backed gaskets with a removable liner, the die cut would slice through all three materials. The liner backing would be the same shape as the rubber and adhesive.

When a die is designed to perform a kiss cut, it allows a bottom layer, such as laminated material, to stay fully intact.

When you’re cutting an adhesive-backed gasket, a kiss cut keeps the liner whole and uncut. You might do this to keep the material contained on a single liner sheet, which can be rolled up and make removal more efficient during production.

Progressive die cutting is sometimes referred to as progressive stamping. When complex shapes are cost-prohibitive in rotary and flat-bed die cutting techniques, progressive die cutting provides an alternative.

Where die cutting uses one die and one shape to get the job done, progressive die cutting uses two more dies, each with a different shape. As the material passes under each die, it takes a different cut so the result is the desired shape.

Flat-bed die cutting, which is also called stamping, uses a steel rule die to guide the blades when stamping out a desired shape with a hydraulic press.

What are the benefits of flat-bed die cutting?

For large-shaped or thicker materials, flat-bed cutting is often recommended over rotary die cutting. Flat-bed die cutting has lower tool-and-die costs than rotary die cutting. Flat-bed die cutting is a cost-effective fabrication method for smaller orders.

If you’re working on a tight deadline, ABLE has partnered with high-quality steel-rule die makers that can expedite orders for a quick turnaround so we can create a shape for your flat-bed die cutting project.

Other Services: Creasing, Perforation and Scoring

When your project requires parts that can bend, fold or stay in place until they’re ready to be detached, our perforation, scoring and creasing capabilities can help you achieve the desired results.

ABLE was founded by Harold H. Martinez in 1974. He later explained that by naming the company “ABLE”. He wanted to convey his mindset to daily life and business. “ABLE” means skill, competence, and talent. That is precisely what he intended to deliver to his customers.