ABLE’s Rapid Prototyping Services for Precision & Innovation

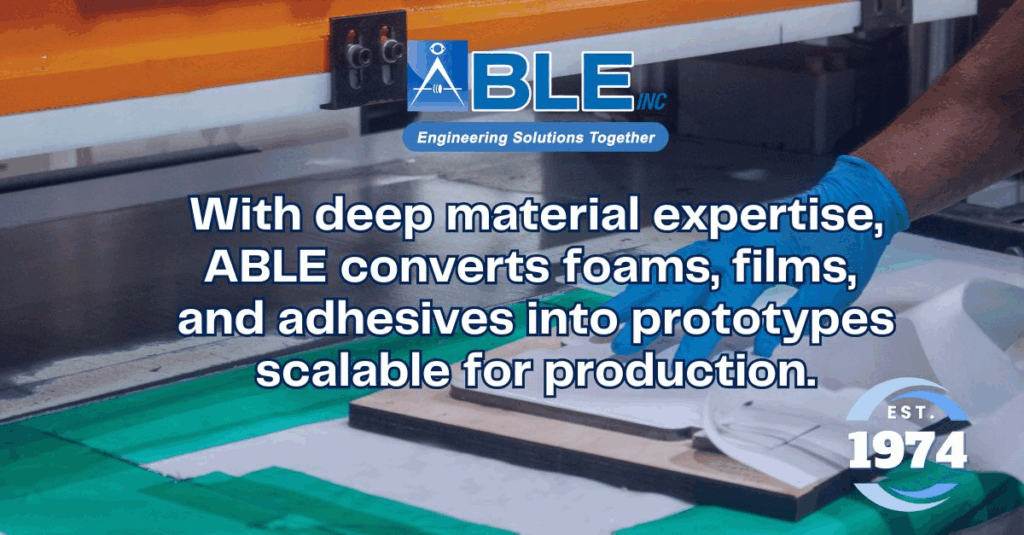

In today’s fast-paced industries, speed and precision are critical in turning ideas into reality. ABLE, with over 50 years of expertise in precision converting and manufacturing solutions, helps businesses accelerate innovation through its rapid prototyping services. By combining advanced equipment, material expertise, and decades of technical know-how, ABLE empowers clients to quickly test, refine, and validate their designs before full-scale production.

What is Rapid Prototyping?

Rapid prototyping is the process of creating a physical model or sample of a product in a short time frame. Unlike traditional methods that often take weeks or months, rapid prototyping allows engineers and designers to evaluate form, fit, and function in days. This not only shortens development cycles but also reduces costs by identifying potential issues early in the process.

Prototyping for Product Testing and Innovation

Rapid prototyping allows companies to bring their designs to life and test them in real situations before moving to full production. Through the establishment of working models, the businesses are able to spot the design weaknesses early and correct them. It is also a process that assists in coming up with new ideas and improving the performance of products. In general, it promotes innovation without exposing the company to expensive errors in high-volume production.

ABLE’s Expertise in Rapid Prototyping

ABLE uses the latest converting technologies and strong material partnerships to deliver prototypes that meet every customer’s needs. The services they offer are die cutting, laser cutting, router knife cutting, and precision slitting. The processes are handled with care in order to achieve accuracy, consistency, and high quality. This implies that all prototypes indicate the same standards as a complete production product.

With ABLE, You Get:

- Speed – ABLE can bring prototypes to life within the shortest time possible, transforming your ideas into real samples. This allows you to experiment, refine, and progress without unnecessary periods of waiting.

- Flexibility – ABLE has numerous materials that it deals with including foams, films, adhesives and composites. This provides you with a greater alternative to locating the correct fit to the design and functionality of your product.

- Accuracy – Prototypes are made with the same advanced tools used for full production. This ensures each sample is precise, consistent, and close to the final product.

- Scalability – After you get your prototype approved, ABLE can transition to bigger production batches quite simply. This hassle-free procedure saves on time, effort and resources.

The Benefits of Rapid Prototyping

Rapid prototyping not only brings about speed, but it also brings genuine benefits to both large and small businesses. It minimizes the development expenses because issues are identified at an early stage, eliminating high-cost errors during large-scale manufacturing. It also reduces the time to market, enabling companies to remain ahead of the others. Most importantly, it allows teams to explore, be innovative, and advance with their designs without fear.

Industries Served

Medical

ABLE designs prototypes of adhesive patches, wearable devices, and other medical components. The prototypes enable healthcare companies to experiment with comfort, safety, and performance. This helps in making sure that the products are capable of being produced on a large scale.

Electronics

ABLE makes prototypes for gaskets, insulators, and protective parts with high precision. These prototypes help electronics companies check for proper fit and reliable function. Testing early ensures fewer problems during full production.

Automotive

ABLE produces prototypes for seat cushions, gaskets, and insulation parts. These allow automakers to test durability, comfort, and precise fit. This helps save time and cost before mass production.

Aerospace

The prototypes are designed to be light and strong to aerospace standards. They are taken through tests to ensure that they can perform effectively in tough conditions. This provides a sense of assurance and reliability.

Renewable Energy

ABLE develops prototypes for batteries, solar panels, and energy storage materials. These prototypes help energy companies test new designs quickly. This allows innovation without sacrificing efficiency or quality.

Why Choose ABLE?

With over 50 years of experience, ABLE is a trusted partner for product development and innovation. Their fast prototyping service is aimed at rapid, accurate, and dependable services. Working with various materials and most state-of-the-art materials, ABLE supports the businesses in developing prototypes that the businesses have a high similar to production quality. This minimizes risks, increases design, and introduces products in the market quickly.

Rapid prototyping is the key to faster, smarter product development. With ABLE, having 50+ years of experience in custom converting solutions, the advanced technology, and the credible processes ensure the business to transform its ideas into reality without unnecessary delays. ABLE offers prototypes that are accurate, scalable, and manufacturing-ready in the medical to renewable energy industries. With ABLE, you will have a partner who is very reliable and helps you to innovate and succeed.

From prototype to production, ABLE is here to help you succeed every step of the way!

References:

https://able123converting.com/capabilities/rapid-prototyping/

https://able123converting.com/blog/able-industry-leading-experts-in-custom-converting-capabilities/