Revolutionizing Product Design: Embracing the Versatility of Silicone Foam

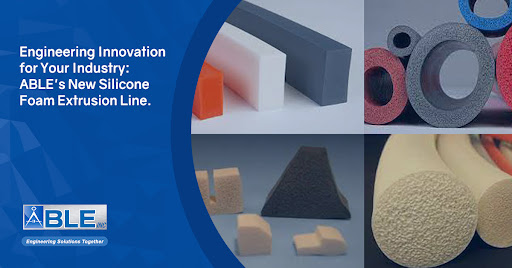

ABLE is pleased to announce the launch of our new silicone foam extrusion line, aimed at providing enhanced services to meet the ever-evolving needs of our valued customers. Our cutting-edge technology enables us to deliver high-quality silicone foam extrusions that are suitable for a wide range of industries and applications.

Whether you require a standard silicone profile extrusion or a custom, complex design, ABLE is dedicated to finding the perfect solution for your specific manufacturing requirements. Our team of experts will work closely with you to understand your unique needs and deliver specialized solutions that align with your goals. With our new silicone foam extrusion line, we are confident in our ability to provide top-notch products that meet the highest standards of quality and precision.

Unleashing Potential: Uncover the Design Flexibility of Silicone Foam

Silicone foam products are produced using platinum-cured liquid silicone rubber. The raw compound is expanded and dispensed on a continuous casting line, followed by a heat-curing process. A diverse range of products with varying densities, softness or firmness, and cell structures is possible by carefully controlling the expansion.

The casting process gives silicone foam materials smooth skin on one or both sides. Open-cell silicone foams are commonly employed for cushioning, dust sealing, or providing light water sealing. On the other hand, closed-cell silicone foam materials are ideal for outdoor gaskets, wash-down gaskets, and resilient cushioning pads. With a firmness range from Ultra Soft to Extra Firm, expanded silicone foam products offer engineers the flexibility to select the most suitable option for their specific applications.

Benefits of Using Silicone Foam

- Impressive Temperature Range: Silicone foam exhibits a wide operating temperature range, spanning from -67°F to 392°F (-55°C to 200°C).

- Effective Water Sealing: The closed-cell silicone foam products offer efficient water sealing capabilities, even with relatively low compressive forces.

- Efficient Dust Sealing: Both open-cell and closed-cell silicone foam products can be utilized for effectively sealing out dust, requiring minimal compressive forces.

- Resistant to Compression Set: Silicone foam demonstrates exceptional resistance to compression set, allowing it to rebound to its original thickness effectively.

- UV and Ozone Resistance: Silicone products exhibit outstanding resistance to UV rays and ozone, which can be attributed, in part, to their inorganic backbone. This property ensures long-term performance and durability.

- UL Gasketing Compliance: Certain silicone foam variants meet UL 94 flame rating standards and are UL 50 and UL 50E-rated for gasketing applications.

Innovative Solutions: Harnessing the Power of Silicone Foam for Product Design

ABLE is proud to offer an extensive selection of extruded profile shapes, encompassing a wide range that extends beyond the following examples:

- “D” Shaped Profiles

- “E” Shaped Profiles

- “H” Shaped Profiles

- “Half Round” Profiles

- “J” Shaped Profiles

- “L” Shaped Profiles

- “P” Shaped Profiles

- “T” Shaped Profiles

- “U” Channel

- Tubing and Cord

- Squares and Rectangles

- Custom Profiles

Silicone Sponge and Foam Materials

Our silicone foam sheet and silicone sponge materials offer exceptional properties for various applications. The closed-cell elastomeric silicone foam sheet is specifically designed to provide reliable sealing, cushioning, vibration insulation, and insulation capabilities. With a range of densities from 200kg/m³ (soft) to 530 kg/m³ (firm), it caters to different requirements. Additionally, it exhibits excellent resistance to ozone, UV rays, and weathering, ensuring long-lasting performance. The closed cell structure enhances its sealing efficiency.

On the other hand, our silicone sponge material excels in environments with extreme conditions, from ozone to UV rays. It boasts an impressive temperature range from -60°C to 230°C, making it an ideal choice for sealing applications in volatile environmental conditions. Available in white, grey, and black, our silicone sponge sheeting offers versatility in design options. Our silicone foam sheet and silicone sponge materials provide reliable solutions for various industries and applications.

Meeting Demand: Silicone Sponge Profiles for Different Applications and Market Needs

Witness the seamless fusion of raw materials, our unrivaled design solutions, and exceptional capabilities converging to craft a uniquely customized part. Leveraging our extensive inventory, in-house machine-cutting expertise, and adept production design, we transcend boundaries in creating precision converter parts with endless possibilities.

Our expertise extends to the supply of silicone sponge profiles, meticulously tailored to cater to various applications and markets. Whether sealing solutions, industrial insulation, automotive components, or other specialized sectors, our silicone sponge profiles deliver unparalleled performance. With a commitment to quality and an unwavering dedication to meeting customer requirements, we ensure that our silicone sponge profiles align seamlessly with the specific demands of various industries and markets – including the following:

- Electrical Enclosure Seals (Electronic, Appliance, Aerospace)

- Insulation for the Electronic, Aerospace, EV, Automotive, and Medical markets

- Outdoor Lighting Gaskets/Industrial Lighting

- HVAC Seals

- Door Seals for the Automotive, Appliance, Aerospace, and Transportation markets

ABLE is proud to introduce our new silicone foam extrusion line, designed to serve our customers’ evolving needs better. With advanced technology and expertise, we deliver high-quality silicone foam extrusions for various industries and applications. Whether it’s a standard or custom design, our dedicated team works closely with customers to provide specialized solutions tailored to their specific manufacturing requirements.

Our silicone foam materials offer impressive temperature range, excellent water and dust sealing capabilities, resistance to compression set, and UV and ozone resistance. In addition, we supply silicone sponge profiles that find application in various industries, such as electrical enclosure seals, insulation, lighting, HVAC seals, and door seals. With our comprehensive range of extruded profiles, silicone sponges, and foam materials, we strive to be the preferred choice for reliable and high-performance sealing and insulation solutions in diverse markets.

Interested in learning more about our silicone foam extrusion offerings? Contact ABLE today and one of our sales engineers will be more than happy to assist you in finding a solution that best fits your needs!

References:

https:// silicone.co.uk/products/silicone-sheeting/silicone-sponge-sheeting/

https:// www.stockwell.com/silicone-foam/