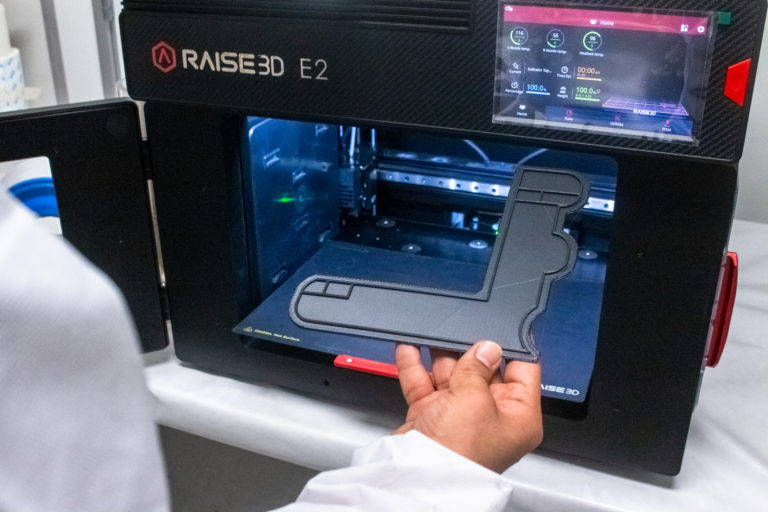

When product design is close to completion, but you need an inexpensive prototype to make sure you found your fit, a rapid prototype has the quick answers you need. ABLE's 3D printing is part of our lineup of in-house rapid prototyping services. 3D printing offers a quick, cost-effective solution for the test samples and proof of concept you need to move your project to production. With ABLE's 3D printing services, we can have the prototype on its way within 48 hours of receipt.

ABLE 3D printing is also known as additive manufacturing. It’s a tech-forward solution to create a 3D prototype of your design with less waiting and less expense. Unlike die cutting a prototype, there’s no need to create special dies or tooling to make the part. All that’s needed is a CAD file of your 3D model.

Once the file is sent to the 3D printer, the machine analyzes the design in a process called slicing. Slicing divides the model into very thin horizontal layers. After the machine formulates a plan to build your 3D model, the printer starts building the model, layer by thin layer, from bottom to top, creating a precise shape, guided by precision instruments.

Building a prototype lets you conceptualize your design before you commit to production. It also can help your team identify any unanticipated issues and design flaws. To help you meet tight deadlines, a rapid prototype built from a 3D printer is a cost-effective way to fill the need.

ABLE was founded by Harold H. Martinez in 1974. He later explained that by naming the company “ABLE”. He wanted to convey his mindset to daily life and business. “ABLE” means skill, competence, and talent. That is precisely what he intended to deliver to his customers.