Need an adhesive, foam or flexible material cut to a specific width? Our many slitting and spooling capabilities cover a wide variety of needs and applications.

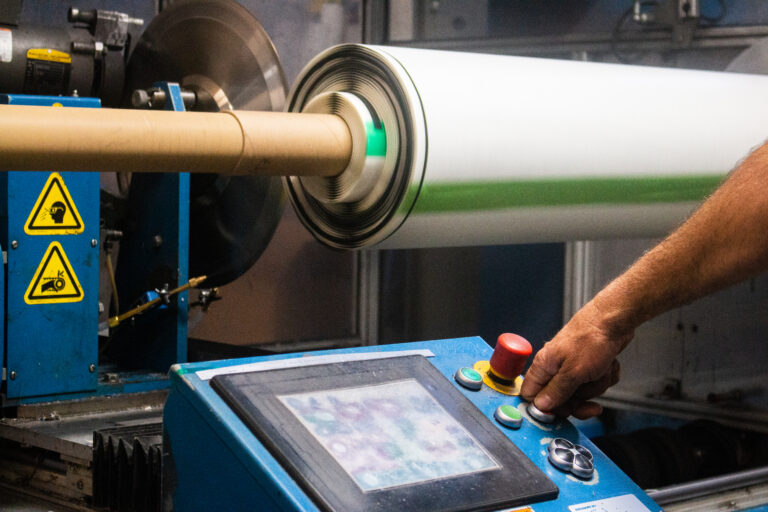

Why lathe slitting? It’s an important step in the converting process to create the right-sized material for your product. Whether you need strips of foam cut to specific dimensions or you need adhesive in a width that’s not available from the manufacturer, ABLE’s precision slitting service is a key capability in our custom converter services.

Lathe slitting is the most common method used to create your custom-sized roll of tape. When you need a pressure-sensitive adhesive in a custom width, and it’s not available from the manufacturer, ABLE’s lathe-slitting services provide a cost-effective solution.

After lathe slitting the master roll, the next step is often spooling. Spooling lets you further customize tape to meet your production needs by combining the rolls of custom cut tape into one large roll.

In a production and assembly that requires rolls of tape, spooling saves time and space. Having one massive roll of material means less storage, less switching and more uptime.

ABLE’s preferred partnership with 3M™ gives us access to the best materials on the market that you can custom cut into the size and shape you need for your project.

ABLE was founded by Harold H. Martinez in 1974. He later explained that by naming the company “ABLE”. He wanted to convey his mindset to daily life and business. “ABLE” means skill, competence, and talent. That is precisely what he intended to deliver to his customers.