Once your converted part is past the design stage, prototyping and testing are the next two hurdles to overcome. That’s where ABLE’s Rapid Prototyping program comes in. We’ll create and ship a prototype of your custom converter product in as little as 48 hours.

Creating a die-cut prototype is a critical final step in the design process. A prototype of your custom converted part provides a high-fidelity representation of the finished part, made to exact dimensions and specifications. A die-cut prototype allows your team to evaluate how the custom converted part looks, feels and performs with the overall product. Before you sign off on the final design, prototyping lets you perform a real-world evaluation of the part.

In industries like medical device and automotive, products must meet strict evaluation processes before they go to market. Tell us up front if prototyping is required to help you meet quality control standards.

When a prototype isn’t a requirement in your quality review, it’s still a smart thing to include in your process to hold the line on quality control. Prototyping has many benefits:

Some of our competitors outsource prototyping to a third party. ABLE’s in-house prototyping services bring better results and here’s how.

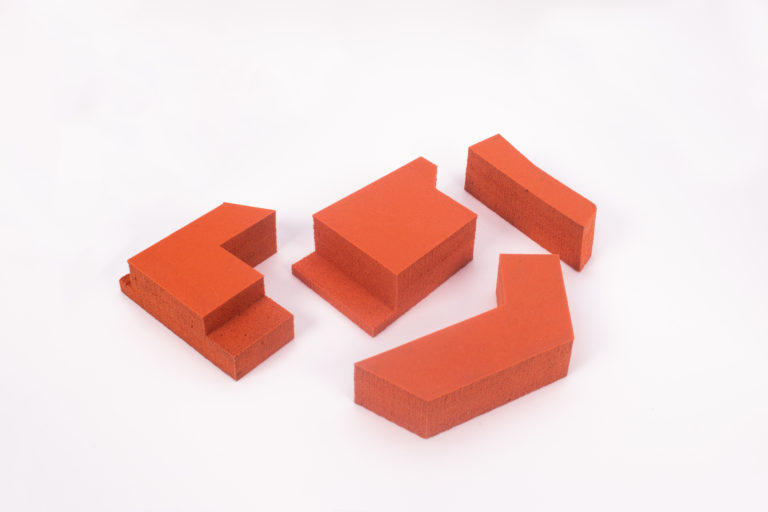

ABLE can create prototypes of your custom converted part from a variety of soft and hard materials, including foam, rubber, silicone and other materials.

Rapid prototyping is one of the last lines of defenses when it comes to developing your project. Prototyping transforms your project from an engineered idea into a physical part, so your team can complete the last round of testing.