ABLE’s capabilities to convert films and foils into usable formats can give your project the finish, functionality and performance you’re looking for. Films and foils can be die-cut, bonded and laminated with other materials. As a custom-converted material, films and foils provide almost infinite possibilities.

Kapton® polyimide film is a material with many unique shielding properties. This opens up a big world of applications across many industries, from aerospace to everyday consumer products. Polyimide can stand up to extreme temperatures (up to 752 degrees Fahrenheit), and boasts the highest UL-94 flammability rating: V-0. Also, polyimide is highly resistant to chemicals, has an exceptionally high dielectric strength and makes an excellent electric insulator.

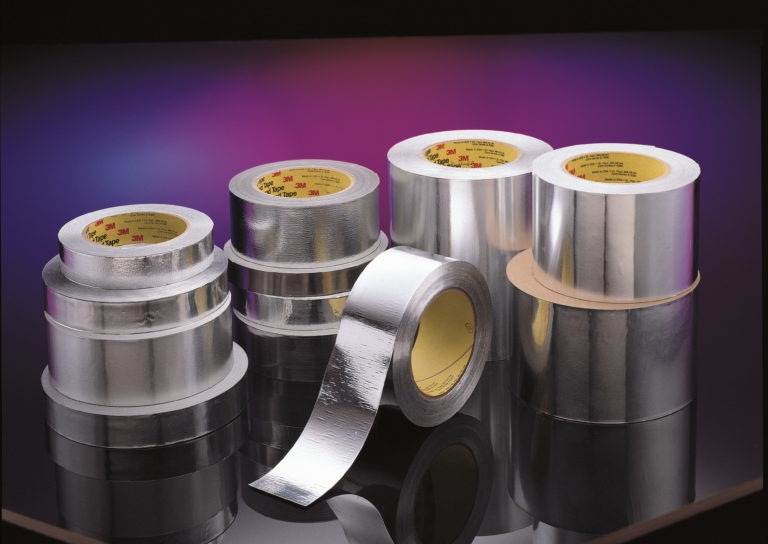

Aluminum with an adhesive backing is highly

convertible and provides many cost-effective

benefits.

Ideal for curved and uneven surfaces, it also makes an effective barrier against moisture and vapor, while providing protection against flame, smoke and chemicals. Converted aluminum tapes can be used for electronics, construction, packaging and more.

Copper tapes provide electro-static shielding while protecting against chemicals and weather conditions. Copper tapes come in conductive and non-conductive types, and can be lined and unlined.

Its multiple medical applications offer the end user long-term comfort with breathability and softness. Used in a variety of medical applications, including device cushioning, head support, furnishings and more.

ABLE was founded by Harold H. Martinez in 1974. He later explained that by naming the company “ABLE”. He wanted to convey his mindset to daily life and business. “ABLE” means skill, competence, and talent. That is precisely what he intended to deliver to his customers.