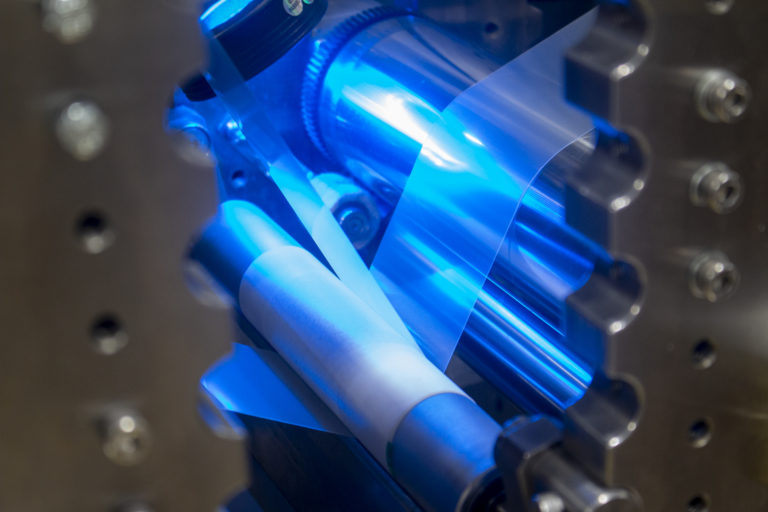

ABLE’s laminating capabilities seamlessly join the materials you need to create the perfect part for your product.

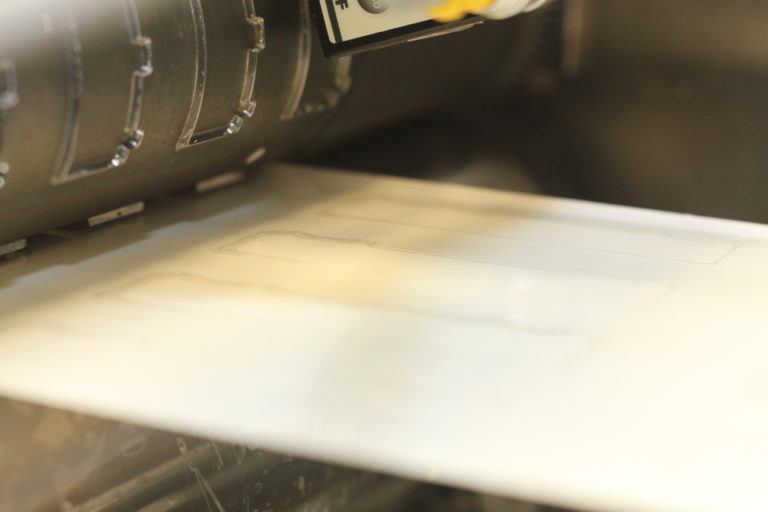

Laminating is a critical step in the converting process. We help you choose the materials you need to create the properties you desire in your custom part. Whether your converter is meant to hold a filter in place, provide insulation in electronics or provide protection against moisture and particulates, our technical experts are here to help.

Laminating dissimilar materials requires an extensive technical knowledge of the adhesives that are available on the market. That’s where ABLE’s expertise can guide you to the best options, thanks to our technical capabilities we’ve gained through the 3M™ Preferred Converter Network.

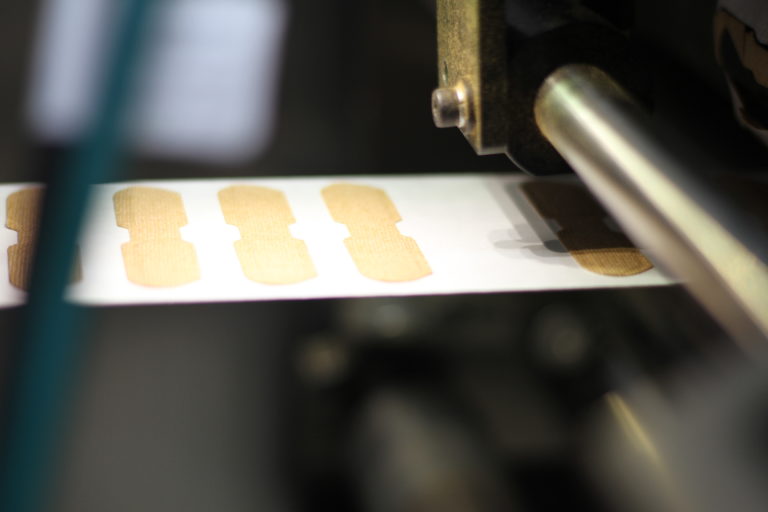

Let ABLE be a key part of your product creation. When you need adhesive coverage in specific zones, laminating becomes more complex. ABLE’s capabilities take your custom part a step further with island placement and zone adhesive coverage. In addition to finding the right process for your product, ABLE can help with material selection when it’s time for laminating services.