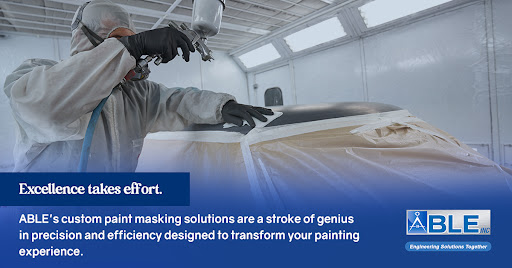

3M Paint Masking Solutions: Promoting Design Without Limits

The automotive industry is continuously changing and this also includes the world of specialty vehicle design. There is much pressure in delivering the latest paint trends but this is usually limited by the reality of its complexity and cost.

ABLE works hand-in-hand with 3M to make these solutions for our clients. Because of this, we are also prepared to offer our clients paint masking solutions that won’t bind them to limits – let’s take a better look at that in this article.

Providing Support: 3M’s Paint Masking Solutions

3M offers comprehensive custom paint masking solutions that are able to work with existing processes and production equipment. These work to create inspiring paint finishes that are efficiently and consistently produced without the need to change the process, equipment, and speed of delivery.

Specifically, there are three applications where 3M’s paint masking solutions can be applied:

- Repair. Usually for small fixes; tapes help to quickly mask around the area that needs repainting. These tapes remove quickly and cleanly when you’re done repainting.

- Multiple Color Designs. Tapes easily and quickly provide a separation line between colors. On the other hand, films are able to cover larger areas to protect the rest.

- Facility Maintenance and Painting. Duct and masking tapes are used for labeling and repairs around facilities; they can also be used to mask floors and walls for paint jobs.

Adding to this, 3M’s paint masking solutions also have the following benefits to further show its reliability:

- Sharp Paint Lines. Minimizes potential frustration and provides consistent delivery of sharp paint lines and designed edges; also resists any slivering or tearing.

- High Temperature Resistance. Great for high temperature paint masking and multiple bake cycles.

- Conforms to Irregular Surfaces. Stretched and adheres to varied surfaces and around corners for easier making of contours and curves.

- Easy to Use. Easy to unwind, apply, and remove.

3M Paint Masking: Reliable Duct and Masking Tape Solutions

Defects can easily get noticed. It’s crucial that any solutions you use are easy to apply and can withstand the necessary bake cycles. After protecting the masked surface, they need to be removed cleanly and easily as well.

As such, 3M has the following masking and duct tapes solutions for their clients:

- Fine Line Masking. Helps to achieve sharp paint lines and separates color for straight lines and curves.

- High Temperature Crepe Masking. Masking for two-tone, multiple color, and custom applications as well as high temperature paint processes.

- Masking Films. Protects large areas from bleed-through and overspray.

- Duct Tapes. Covers any seals and openings.

Product Solutions for Paint Masking

Whether you’re making paint repairs or masking parts, you need to choose the right products and processes to help increase efficiency. 3M’s masking products are engineered to not only withstand temperatures or remove cleanly, but they’re also engineered to stick firmly to substrates.

That said, here are a couple of 3M’s paint masking solutions to help you find the appropriate one for you.

3M Adjustable Paint Masking Applicator

An applicator designed for OEMs as a robust, lightweight, and intuitive tool for masking complex surfaces. This tool includes application tips that can be adjusted to the precise depth required. It also has magnets to help keep the tool aligned while a cutter block helps to increase the machine’s productivity.

Masking Tapes

- Performance Masking Tape 2380. Features high-temperature resistance and provides strong holding power; crepe paper backing prevents bleed-through.

- Premium High Temperature Masking Tape 2693. Mini-crepe paper that’s smooth and heavy duty; great for multi-bake paint cycles and features aggressive holding.

- High Performance Green Masking Tape 401+. Best for critical paint masking applications that need a strong hold; conformable for ease of use.

Fine Line Tapes

- Scotch Fine Line Tape 218. Great solvent and moisture resistance; stiffer than other vinyl fine line tapes and often used as a layout tape for custom, multi-color, and high value painted graphics.

- Scotch High Temperature Fine Line Tape 4737. Removes cleanly and provides conformability for straight lines and curves.

- Scotch Masking Tape 2800. Leaves no residue on plastic parts and features high conformability.

Masking Films

- High Temperature Paint Masking Film 7300. Provides conformability and good drape that’s designed for soft flexing; protects against bleed-through; eliminates fiber.

- High Temperature Paint Masking Film 7302. A wide area masking film that’s designed to not damage surfaces; is also flexible.

- Ultra High Temperature Masking Film 7305. Fights against bleed-through; seals against paint, lacquers, enamels, and solvents.

Duct Tapes

- Performance Plus Duct Tape 8979. 6-month clean removal.

- Extra Heavy Duty Duct Tape 6969. Water resistant and heavy duty.

It’s important to keep up with the latest paint trends and what better way to do that than to use the power of 3M’s paint masking solutions. As these solutions allow the repair of even old devices, they are great options for anyone who is trying to update to the latest trends but are having a hard time finding the right solutions for them. Fortunately, 3M is partnered with ABLE to deliver these solutions to their clients.

Interested in learning more about 3M’s paint masking solutions? Talk to us today and we’ll be more than happy to assist you with the challenges that you might be facing.

Sources:

https:// www.3m.com/3M/en_US/commercial-specialty-vehicles-us/applications/paint-masking-solutions/

https:// www.3m.com/3M/en_US/automotive-manufacturing-and-assembly-us/areas-of-assembly/paint-shop/

https:// www.3m.com/3M/en_US/automotive-manufacturing-and-assembly-us/product-solutions/masking-tapes-films/